扫一扫 添加小助手

服务热线

13818320332

扫一扫 关注我们

9月22日,FDA公布一封针对印度无菌制剂企业的警告信。主要的违规项涉及:缺少有关微生物鉴定和内毒素分析;未能建立适当的系统,来监测无菌工艺区域的环境条件,包括压差、粒子监测等。

9月22日,FDA公布一封针对印度无菌制剂企业的警告信。主要的违规项涉及:缺少有关微生物鉴定和内毒素分析;未能建立适当的系统,来监测无菌工艺区域的环境条件,包括压差、粒子监测等。

在该警告信中,对于实验室检验,FDA特别指出:分析人员没有使用经校验的计时器(calibrated timer),来对方法中的步骤进行计时,而是使用了未经校验的挂钟(wall clock)。

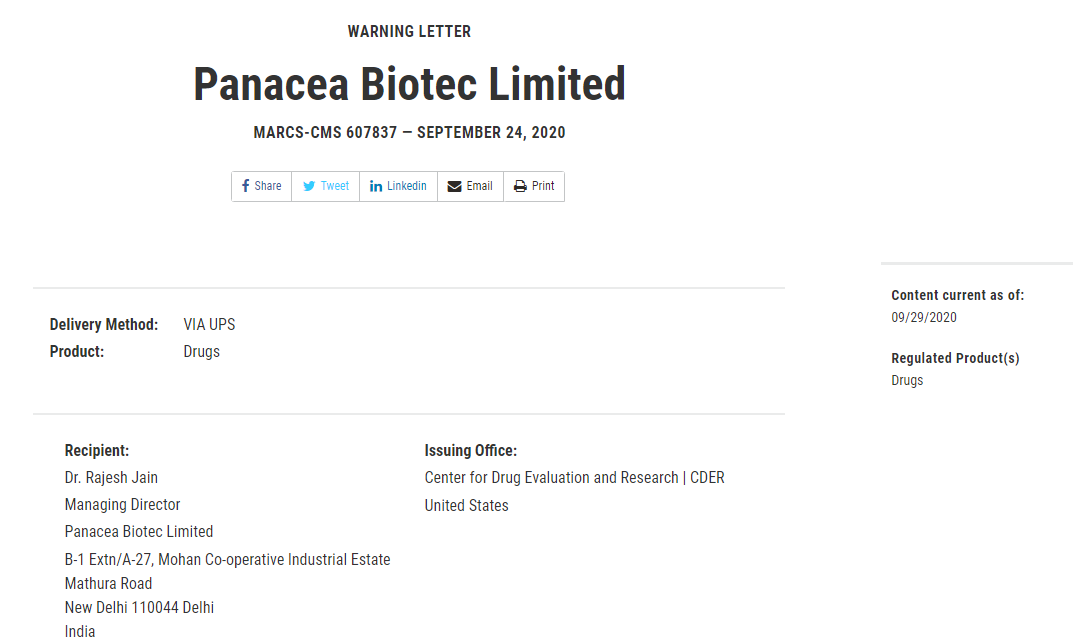

Warning Letter 320-20-48

September 24, 2020

Dear Dr. Jain:

警告信320-20-48

2020年9月24日

Jain 博士:

The U.S. Food and Drug Administration (FDA) inspected your drug manufacturing facility, Panacea Biotec Limited, FEI 3007187282, at Tehsil Nalagarh, Village Malpur, Baddi, District Solan, Himachal Pradesh, from February 10 to 20, 2020.

2020年3月9日至12日,美国FDA检查了你的药品生产工厂Panacea Biotec Limited,FEI 3007187282,位于印度喜马偕尔邦。

This warning letter summarizes significant violations of current good manufacturing practice (CGMP) regulations for finished pharmaceuticals. See Title 21 Code of Federal Regulations (CFR), parts 210 and 211 (21 CFR 210 and 211).

该警告信总结了严重违反制剂CGMP规定的情况。请参阅21CFR第210和211部分。

Because your methods, facilities, or controls for manufacturing, processing, packing, or holding do not conform to CGMP, your drug products are adulterated within the meaning of section 501(a)(2)(B) of the Federal Food, Drug, and Cosmetic Act (FD&C Act), 21 U.S.C. 351(a)(2)(B).

由于你用于生产、加工、包装或储存的方法、设施或控制措施不符合CGMP,因此根据FD&C法案501(a)(2)(B)条及21 U.S.C.351(a)(2)(B) 条的规定,你的药品被认为是掺假。

We reviewed your March 13, 2020, response to our Form FDA 483 in detail and acknowledge receipt of your subsequent correspondence.

我们详细审查了你2020年3月13日对FDA 483表格的答复,并确认收到你的后续信件。

During our inspection, our investigator observed specific violations including, but not limited to, the following.

在我们的检查过程中,调查员发现了具体的违规行为,包括但不限于以下行为。

微生物鉴定问题

1. Your firm failed to establish laboratory controls that include scientifically sound and appropriate specifications, standards, sampling plans, and test procedures designed to assure that components, drug product containers, closures, in-process materials, labeling, and drug products conform to appropriate standards of identity, strength, quality, and purity (21 CFR 211.160(b)).

1.你的公司未能建立包括科学合理且适当的质量标准、标准、取样计划和检验程序在内的实验室控制措施,以确保组件、药品容器、密封件,在制品、标签和药品符合相关规定,即鉴别、强度、质量和纯度的标准(21 CFR 211.160(b))。

Your firm lacked data on microorganism identification from your aseptic processing operation.

你的公司缺少无菌工艺操作中有关微生物鉴定的数据。

Your microbiology laboratory is responsible for identifying microorganisms recovered from your firm’s environmental monitoring (EM) program. Your procedure, Isolation and Identification of Microbial Isolates SOP BFI-QC-060 Rev No. 02, requires identification of isolates to the genus (and “preferably” species) level when they are considered to be morphologically different from previously identified isolates.

你的微生物实验室负责鉴定从公司的环境监测(EM)程序中回收的微生物。你的程序“微生物分离物的分离和鉴定SOP BFI-QC-060 Rev. 02”,要求将分离物鉴定为属(“最好”是种)水平,前提是它们在形态上不同于先前鉴定的分离物。

However, you rarely identified microbes recovered from your aseptic processing operation and lacked meaningful data on microbes in your aseptic processing room. Notably, in 2019, your firm identified only one organism of the 6360 microorganisms isolated from the ISO 7 area.

但是,你很少鉴别从无菌工艺操作中回收的微生物,并且缺乏有关无菌工艺室中微生物相关的有意义数据。值得注意的是,在2019年,对于ISO 7级洁净室中分离出的6360个微生物,你的公司仅鉴别了其中一种。

Furthermore, you attempted to visually “identify” recovered microorganisms using an incomplete and crude photographic library consisting of only (b)(4) microbes.

此外,你尝试目视“鉴别”回收的微生物,这一过程中使用了不完整且粗糙的仅由XX个微生物组成的照片库。

n addition to lacking microbial identification data from aseptic processing operations, your laboratory also failed to maintain basic microbial differentiation information. For example, you often failed to record bacterial gram stain data, determine whether microbes were sporeformers, or provide other critical differentiating data.

除了缺乏来自无菌工艺操作的微生物鉴定数据外,你的实验室还无法维护基本的微生物分化信息。例如,你经常无法记录细菌革兰氏染色数据,无法确定微生物是否为产孢子菌,也不能提供其它重要的区分数据。

Routine characterization of recovered isolates provides vital data to promptly detect potential routes of contamination in aseptic operations and take action to prevent sterile drug contamination. Because your firm lacks microbial identification data from environmental monitoring, you lack basic information needed to evaluate the ongoing state of control of your aseptic manufacturing operations.

对回收的分离物进行常规表征可提供重要数据,以迅速检测出无菌操作中潜在的污染途径,并采取措施防止无菌药物污染。你的公司缺少来自环境监测的微生物鉴别数据,因此你缺少评估无菌生产操作的持续控制状态所需的基本信息。

Your response stated that you would differentiate and attempt to presumptively identify environmental isolates based on colony morphology. In addition, you stated you would perform a gram stain on isolates recovered from your ISO 5 and 7 areas. Your response is inadequate. You did not commit to identifying all isolates recovered throughout your aseptic processing rooms to at least the genus level (and species, whenever possible).

你的答复表明,你将根据菌落形态,区分并尝试推测性地鉴定环境分离株。此外,你还说过要对从ISO 5和7区域回收的分离物进行革兰氏染色。你的回应不充分。对于在整个无菌工艺室所有分离株,你并没有承诺中至少鉴定出属(以及可能的种)的。

Also, you did not commit to implement a sufficient microbial identification program for ancillary cleanrooms. For ancillary cleanrooms, identification of isolates should occur at an adequate frequency to provide a current database of microflora, and other isolates from these areas should be differentiated with higher specificity than your procedures currently prescribe.

另外,你没有承诺为辅助洁净室实施足够的微生物鉴定程序。对于辅助洁净室,应该以足够的频率对分离株进行鉴定,以提供当前的菌群数据库,并且应该以比你目前规定的程序更高的特异性,来区分来自这些区域的其它分离株。

Endotoxin Analysis 内毒素分析

During the inspection, we observed the analysis of water samples and (b)(4) samples for endotoxin using the gel clot method. We observed that the analyst failed to perform the critical steps for vortexing samples. Additionally, the analyst failed to use a calibrated timer for timing the steps in the method and instead used a wall clock that had not been calibrated. Vortexing and timing are critical steps for this method to ensure that testing does not yield false negative results. Your gel clot method also failed to include sufficient instructions.

在检查过程中,我们观察到了使用凝胶凝结法分析水样品和XX样品中的内毒素。我们观察到分析人员未能执行涡旋样品的关键步骤。此外,分析人员没有使用已校验的计时器,来对方法中的步骤进行计,而是使用了未经校验的挂钟。涡旋和定时是该方法的关键步骤,以确保检验不会产生假阴性结果。你的凝胶凝结法也没有包含足够的说明。

your procedure to include vortexing steps, as well as use a calibrated external thermometer and a calibrated external timer. You also stated that, as a part of your investigation to assess impact on the product, you analyzed reserve samples of all commercial batches of (b)(4) injection (b)(4) mg/vial and all batches complied with the acceptance criteria.

你的回答承认你的方法不充分,你将修改程序以包括涡旋步骤,并使用已校验的外部温度计和已校验的外部计时器。你还声明,作为评估对产品影响的调查的一部分,你分析了XX注射剂XX mg /瓶的所有商业批次的留样,所有批次均符合可接受标准。

Your response is inadequate. You failed to perform a retrospective review of your laboratory practices including but not limited to the adequacy of your test methods. You also did not provide an evaluation of analyst competencies and training sufficiency.

你的回应不充分。你没有对实验室实践进行回顾性审查,包括但不限于检验方法的充分性。你也没有提供对分析人员能力和培训充分性的评估。

In response to this letter, provide the following:

针对此信,请提供:

• A comprehensive, independent assessment of your laboratory practices, procedures, methods, equipment, documentation, and analyst competencies. Based on this review, provide a detailed plan to remediate and evaluate the effectiveness of your laboratory system. Areas of special emphasis in your retrospective assessment and corrective action and preventive action (CAPA) plan should include, but not be limited to:

•对你的实验室操作、程序、方法、设备,文档和分析人员的能力进行全面、独立的评估。在此审查的基础上,提供详细计划,以补救和评估实验室系统的有效性。在回顾性评估以及纠正和预防措施(CAPA)计划中,应特别强调的领域应包括但不限于:

o Review all laboratory test methods to ensure they are well-defined in order to enable reproducibility, and remediate any gaps in specificity that are identified

o复查所有实验室检验方法,确保其定义明确,以确保可重复性,并弥补任何确定的特异性差距

o Ensure adequate calibration frequencies for lab equipment (e.g., heating block thermometer). Include your SOP with remediated frequencies

o确保实验室设备(例如加热块温度计)具有足够的校验频率。提供含频率修改后的SOP

环境监测

2. Your firm failed to establish an adequate system for monitoring environmental conditions in aseptic processing areas (21 CFR 211.42(c)(10)(iv)).

2.你的公司未能建立适当的系统,来监测无菌工艺区域的环境条件(21 CFR 211.42(c)(10)(iv))。

Your firm manufactures (b)(4) injection (b)(4)mg/vial for the U.S. market. Our inspection revealed deficient ongoing monitoring and control of your aseptic processing facility.

你的公司为美国市场生产XX注射剂,XX毫克/瓶。我们的检查发现,你的无菌工艺设施缺乏持续的监测。

Pressure Differentials压差

You lacked an effective system to ensure adequate control of differential pressures in your aseptic processing facility. You manually recorded differential pressures between cleanrooms approximately (b)(4) during a (b)(4).

你缺乏有效的系统,来确保对无菌工艺设施中压差进行适当控制。你手动记录洁净室压力差为XX。

You also allowed excursions up to (b)(4), including pressure reversals. Notably, for excursions beyond (b)(4), a deviation/incident “may” be proposed.

你还允许XX范围的偏移,包括反向压力。值得注意的是,对于超出XX的偏移,“可能”会启动偏离/事件程序。

You also lacked an adequate, integrated system for frequently recording room differential pressure during a (b)(4), scrutinizing ongoing HVAC control, initiating deviations, and taking appropriate actions when pressure excursions occur.

你还缺少一个足够的集成系统,无法在XX期间频繁记录房间压差,仔细持续检查HVAC控制,并在发生压力偏移时启动偏差,采取适当的措施。

Because of your inadequate pressure differential systems, and insufficient standards for initiating investigations of pressure control issues, you lack evidence that ongoing control was maintained for the HVAC systems used in your aseptic processing operations.

由于压差系统不足,并且没有足够的标准来启动对压力控制问题的调查,因此,你缺乏证据证明:对无菌工艺操作中使用的HVAC系统保持了持续控制。

A suitable facility monitoring system is critical to maintain appropriate air quality throughout all of your cleanrooms. All alarms and deviations from established limits should be appropriately investigated to rapidly detect atypical changes that can compromise the facility’s environment. Prompt detection of an emerging low-pressure problem is essential to preventing ingress of lower quality air into a higher criticality room.

合适的设施监测系统,对于在所有洁净室中保持合适的空气质量,至关重要。对所有警报和偏离既定限值的情况,应进行适当调查,以迅速检测出可能危害设施环境的非典型变化。及时发现新出现的低压问题,对于防止低质量空气进入较高级别的关键房间,是至关重要的。

Your response stated you are implementing a new system that focuses on monitoring online differential pressures for the (b)(4) (filling line). However, you did not commit to a comprehensive review of your facility monitoring and HVAC systems to improve environmental control in all cleanrooms of the aseptic processing facility.

你的回答表明你正在实施一个新系统,该系统专注于监测XX(灌装线)的在线压差。但是,你并未承诺对设施监测和HVAC系统进行全面审查,针对无菌工艺设施所有洁净室,来改善环境控制。

Non-Viable Particulate Monitoring粒子监测

You lacked an adequate system for handling non-viable particulates (NVP) above your action level of (b)(4) NVP ≥ 0.5 μm/ftᶾ during aseptic processing operations.

对于悬浮粒子(NVP),你没有足够的系统,处理无菌工艺操作中高于行动限NVP≥0.5μm/ftᶾ的情况。

This limit was exceeded for seven out of (b)(4) batches of (b)(4) injection mg/vial manufactured since May 2019. You lacked investigations in response to the high particulate levels observed in the ISO 5 aseptic processing operation. Per your NVP monitoring procedure, an investigation was not required unless an excursion lasted longer than (b)(4).

对于自2019年5月生产的X批注射剂,有七批超限。对于ISO 5无菌工艺操作中发现的高粒子水平,你缺乏调查。根据你的NVP监测程序,除非偏移持续的时间长于XX,否则无需进行调查。

Excessive particulates in the ISO 5 environment can lead to nonviable or biological contamination of sterile drug products.

ISO 5级环境中的粒子过多,会导致无菌药品的颗粒或微生物污染。

In your response, you stated that you are in the process of evaluating the feasibility of implementing an integrated non-viable particulate counter within the (b)(4) which will enable the filling machine to stop when an excursion occurs.

在答复中,你说明,你正在评估在XX中实施集成的粒子计数器的可行性,该计数器将使灌装机在发生偏移时停止运行。

Although you have committed to improvements in your non-viable particulate monitoring program, you lacked sufficient information on the parameters that trigger investigations.

尽管你一直致力于改善粒子监测程序,但是你缺乏有关触发调查参数的足够信息。

In response to this letter, provide the following:

针对此信,请提供:

• A thorough, independent assessment, and CAPA for your pressure differential system. Include a comprehensive evaluation of monitoring, recording, alarm documentation, deviation investigation, data retention and overall system control in your assessment. Provide a CAPA that includes but is not limited to:

•为你的压差系统进行全面、独立的评估和CAPA。在评估中包括对监测、记录、警报文档、偏差调查、数据保留和整体系统控制的全面评估。提供CAPA,包括但不限于:

o The state of control of air balance between clean areas and adequacy of integration of each of the HVAC systems

o清洁区域之间的空气平衡控制状态,以及每个HVAC系统的集成度是否足够

o Documentation for all alarms, irrespective of the length or location of the event and retention of this data

o所有警报的文档,无论事件的长度或位置、以及是否保留该数据

o Remediated procedures for investigating deviations from established limits, and specific provisions for handling instances in which a pressure reversal occurs

o用于调查偏离既定限值的补救程序,以及处理发生反向压力的具体规定

o Remediated facility monitoring systems that will rapidly detect atypical changes of pressure in one or more cleanrooms simultaneously

o修复后的设施监测系统,可同时快速检测一个或多个洁净室中压力的非典型变化

o A detailed description of how you will ensure uninterrupted power supply (UPS) for all HVAC systems supporting each cleanroom in your facility

o详细说明:为你设施中每个洁净室的所有HVAC系统,如何确保提供不间断电源(UPS)

• Comprehensive risk assessment of all contamination hazards with respect to your aseptic processes, equipment, and facilities. Provide an independent assessment that includes, but is not limited to:

•针对无菌工艺、设备和设施的所有污染危害,提供全面风险评估。提供独立的评估,包括但不限于:

o All human interactions within the ISO 5 area

o ISO 5区域内的所有人员交互

o Equipment placement and ergonomics

o设备放置和人体工程学

o Air quality in the ISO 5 area and surrounding room

o ISO 5区域和周围房间的空气质量

o Facility layout

o设施布局

o Personnel Flows and Material Flows (throughout all rooms used to conduct and support sterile operations)

o人物流(贯穿所有用于进行和支持无菌操作的房间)

o Aseptic practices and cleanroom behavior during production

o生产过程中的无菌操作和洁净室行为

o Identification of your intrinsic and extrinsic particulate risks to your aseptic processing operations. Also assess the adequacy of current ISO 5 area particulate monitoring procedures (including but not limited to evaluating the maximum time that may elapse before a particulate excursion alarm occurs)

o确定你的无菌工艺操作的内在和外在粒子风险。还要评估当前ISO 5区域粒子监测程序的适当性(包括但不限于:评估发生粒子偏移警报之前,可能保持的最长时间)

• A detailed remediation plan with timelines to address the findings of the contamination hazards risk assessment. Describe specific tangible improvements to be made to aseptic processing operation design and control.

•详细的修复计划和时间表,以解决污染危害风险评估的结果。针对无菌工艺操作设计和控制,描述要进行的具体切实改进。

See FDA’s guidance document, Sterile Drug Products Produces by Aseptic Processing – Current Good Manufacturing Practice, to help you meet the CGMP requirements when manufacturing sterile drugs using aseptic processing, at https://www.fda.gov/media/71026/download.

请参阅FDA的指南,“无菌工艺生产的无菌药品-cGMP”,以帮助你在使用无菌工艺生产无菌药物时,达到CGMP要求,网址为(见上)。

顾问推荐

Based upon the nature of the violations we identified at your firm, we strongly recommend engaging a consultant, qualified as set forth in 21 CFR 211.34, to assist your firm in meeting CGMP requirements.

根据我们在你公司中发现的违规行为的性质,我们强烈建议雇用一名符合21 CFR 211.34规定的合格顾问,以帮助你的公司满足CGMP要求。

Your use of a consultant does not relieve your firm’s obligation to comply with CGMP. Your firm’s executive management remains responsible for resolving all deficiencies and systemic flaws to ensure ongoing CGMP compliance.

你聘用顾问并不能免除公司遵守CGMP的义务。你公司的执行管理层仍然负责解决所有缺陷和系统性缺陷,以确保持续符合CGMP。

结论

The violations cited in this letter are not intended to be an all-inclusive list of violations that exist at your facility. You are responsible for investigating and determining the causes of these violations and for preventing their recurrence or the occurrence of other violations.

本信函中引用的违规行为并非旨在列出与你产品相关的所有违规行为。你有责任调查和确定这些违规的原因,并防止其再次发生或发生其它违规情况。

If you are considering an action that is likely to lead to a disruption in the supply of drugs produced at your facility, FDA requests that you contact CDER’s Drug Shortages Staff immediately, at drugshortages@fda.hhs.gov, so that FDA can work with you on the most effective way to bring your operations into compliance with the law. Contacting the Drug Shortages Staff also allows you to meet any obligations you may have to report discontinuances or interruptions in your drug manufacture under 21 U.S.C. 356C(b). This also allows FDA to consider, as soon as possible, what actions, if any, may be needed to avoid shortages and protect the health of patients who depend on your products.

如果你考虑采取的行动可能会导致你药物的供应中断,则FDA要求你立即联系CDER的药物短缺人员(drugshortages@fda.hhs.gov),以便FDA可以与你以最有效的方式沟通,使你的运营符合法律规定。根据21 USC 356C(b),与药品短缺人员联系,还可以使你履行报告药品供应中断的义务。这也使FDA可以尽快考虑可能需要采取什么措施,以避免短缺,并保护依赖你产品的患者的健康。

Until you correct all violations completely and we confirm your compliance with CGMP, FDA may withhold approval of any new drug applications or supplements listing your firm as a drug manufacturer.

在你完全纠正所有违规行为、且我们确认你遵守CGMP之前,对于新药申请或补充申请,FDA可能会拒绝批准将你的公司列为药品生产商。

Failure to correct these violations may also result in the FDA refusing admission of articles manufactured at Tehsil Nalagarh, Malpur Baddi, District Solan, Himachal Pradesh, into the United States under section 801(a)(3) of the FD&C Act, 21 U.S.C. 381(a)(3). Articles under this authority may be subject to refusal of admission, in that the methods and controls used in their manufacture do not appear to conform to CGMP within the meaning of section 501(a)(2)(B) of the FD&C Act, 21 U.S.C. 351(a)(2)(B).

根据FD&C法案21 801(a)(3)条与USC 381(a)(3) 条,不纠正这些违规行为也可能导致FDA拒绝接纳该工厂生产的产品,无法进入美国。对于该法案授权下的产品,可能会被拒绝入境,因为其生产使用的方法与控制不符合CGMP,CGMP是在FD&C法案21(501)(a)(2)(B) 条与USC 351(a)(2)(B) 条中被要求的。

After you receive this letter, respond to this office in writing within 15 working days. Specify what you have done since our inspection to correct your violations and to prevent their recurrence. If you cannot complete corrective actions within 15 working days, state your reasons for delay and your schedule for completion.

收到这封信后,请在15个工作日内以书面形式答复FDA办公室。说明自我们检查以来,你所做的事情,以纠正你违规行为,并防止其再次发生。如果你无法在15个工作日内完成纠正措施,请说明延误原因和完成时间表。

If you believe that your products are not in violation of the FD&C Act (or you have complied with FDA regulations), include your reasoning and any supporting information for our consideration.

如果你认为你产品未违反FD&C法案(或你已遵守FDA法规),请提供你理由和任何支持信息,以供我们考虑。

文章来源:PharmLink

本网站刊载的所有内容,包括文字、图片、音频、视频、软件等,如非标注为“原创”,则相关版权归原作者所有,如原作者不愿意在本网站刊登相关内容,请及时通知本站,我们将第一时间予以删除。